Among some of the more challenging locations that The LED Industrial Lighting Co. has surveyed, are the container cranes at the Royal Portbury Docks which are part of the Port of Bristol.

The Port of Bristol is one of the fastest growing ports in the UK. This deep-water dock looks out over the Severn Estuary. It is a major port for the import of vehicles and containers into the UK and has the largest entrance lock into any UK port, accommodating vessels up to 41m beam, 290m length and 14.5m draft.

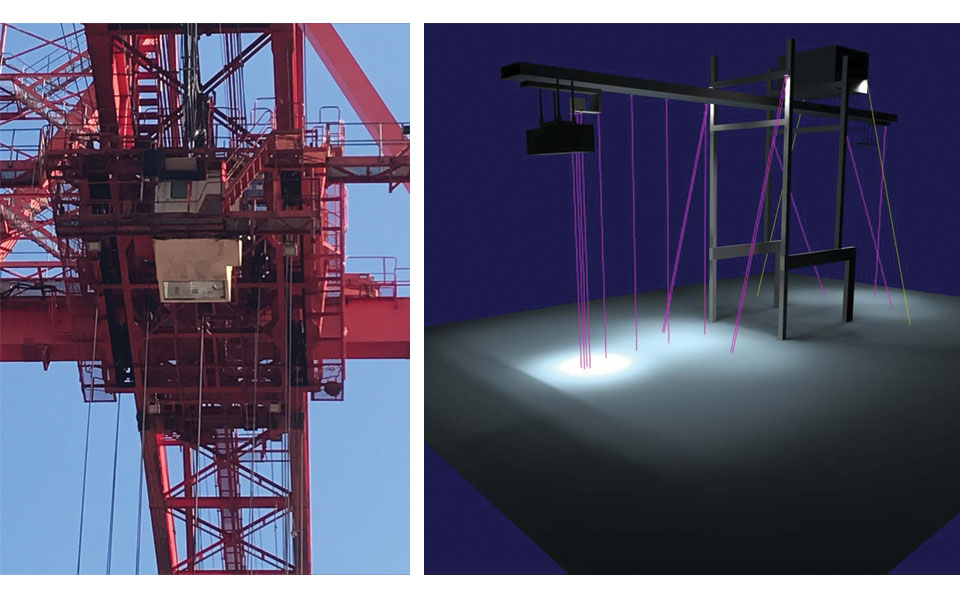

There are a number of cranes at Royal Portbury and in 2016, Crane 2 required a lighting refurbishment. The existing 1000W HPS floodlights were located along the boom, backreach and beneath the driver cabin at approximately 30m above the quayside.

Maintenance-free LED Solution against saline spray

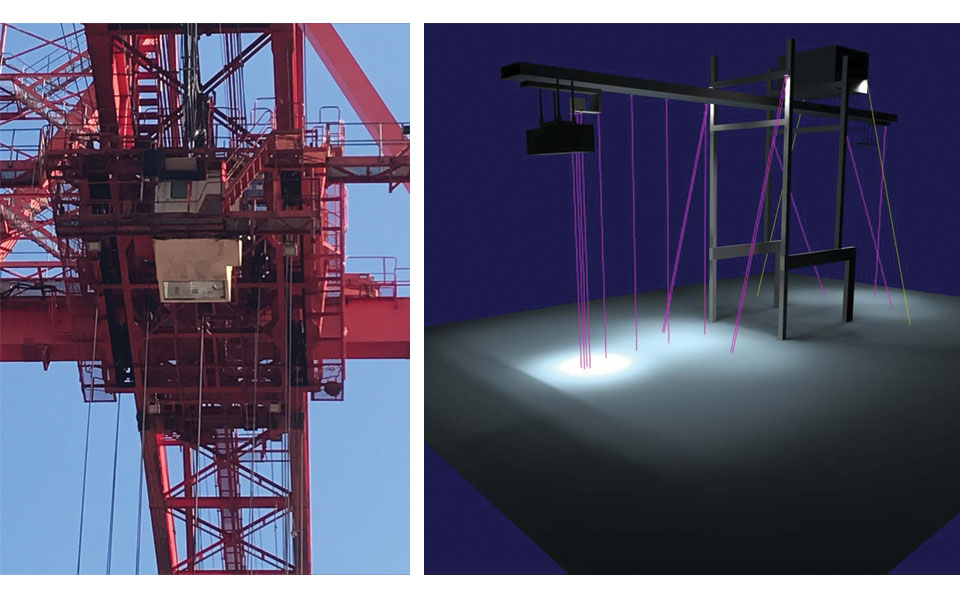

The project brief was to provide a maintenance-free LED solution and to achieve 150 lux on the vessel deck under the driver’s cabin. Given the harsh marine environment, the fittings required to be IP66 and protected against the extreme corrosion of saline spray.

The existing fittings were corroding and many of the lamp bulbs failed due to the lifting boom and vibration from wind and quayside trackway. Some of the floodlights were also very difficult to access and required specialist cherry-pickers to be hired, with the inevitable cost.

Following a survey of the crane and quayside, a lighting design was commissioned. The engineers required to re-use the existing lamp positions, so identifying an LED solution to provide 150 lux under the driver cabin would prove challenging.

After some discussion, the design team selected the 14,500lm Dialight Vigilant Floodlight. Whilst only 140W, a 520 narrow beam option was used. With the four floodlights grouped immediately around the cabin, it was possible to achieve 162 lux at 0.00m.

The Dialight Floodlight benefited from a number of beam angles, but importantly it has a lockable stainless steel mounting bracket. More powerful fittings were available but they were mounted using adjustable brackets which could not be locked. With the main boom being lifted during non-work hours, there was concern that without the locking mechanism, the lights would swivel and become unaligned.

The compromise with the Dialight solution was that there were significantly lower lux values down the length of the boom, as no single LED fitting would be able to replace a 1000W HPS. It was felt however, that this was wasted light, and the priority was for the driver to see beneath the cabin. Additional floodlighting could be installed around the legs of the crane to give general illumination at quayside.

The lights were purchased and installed in the summer of 2016. Whilst the crane crew took a few weeks to adjust to the new light footprint from the narrow beam LEDs, the luminaires have continued to work successfully since. Bristol Port Company has the additional benefit of a 10 year warranty on these fittings, offering peace of mind and significantly reduced maintenance costs.