Bristol Port is one of the leading dry bulk cargo handling terminals in the UK, with facilities at both Royal Portbury Dock and Avonmouth Dock. Together with the loading and discharging facilities, large investments have been made in bulk warehousing including the upgrading of lighting infrastructure.

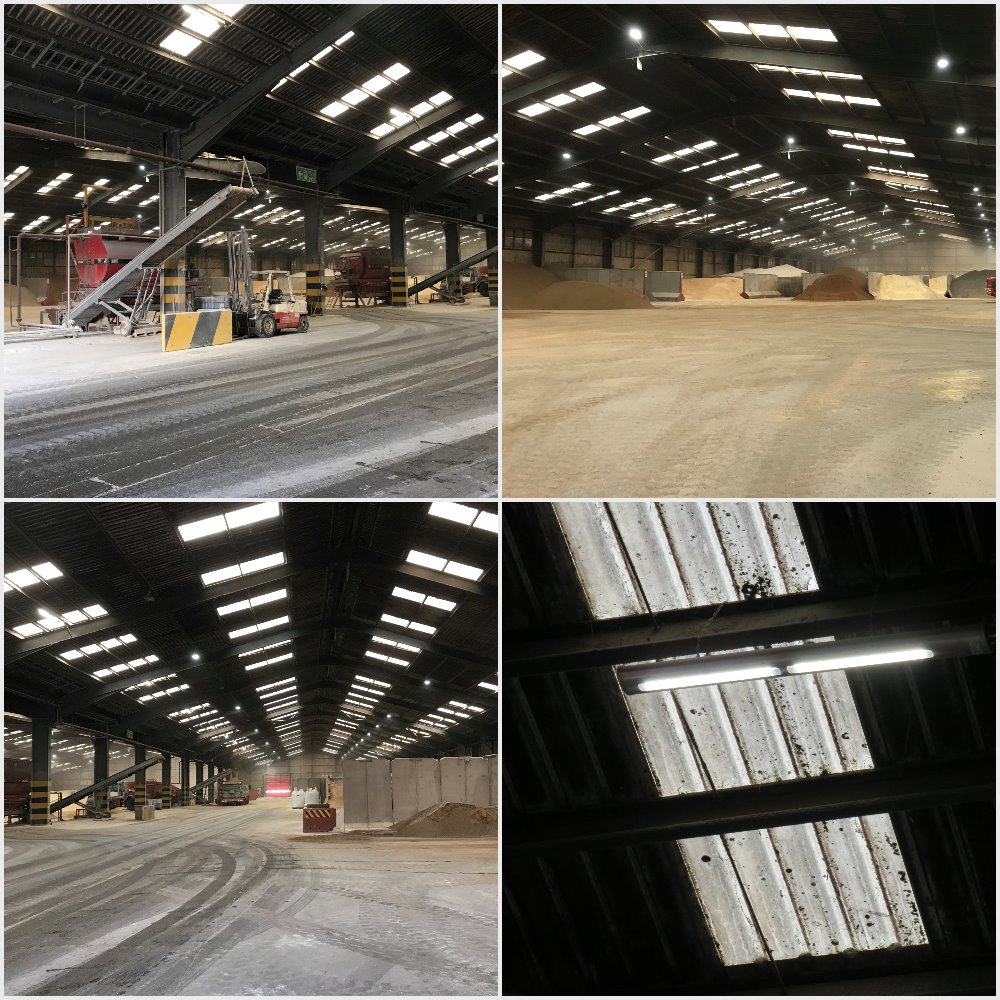

G Shed is a dedicated animal feed warehouse offering storage, blending and milling of animal feeds and grains. The operations within the shed required a wholesale upgrade to hazardous area fittings, including provision of emergency lighting. The work also enabled the traditional discharge floodlighting to be replaced with LED products. LED Industrial Lighting Co. Ltd provided options for a number of LED manufacturers, with the Dialight Safesite offering the most competitive and compelling solution.

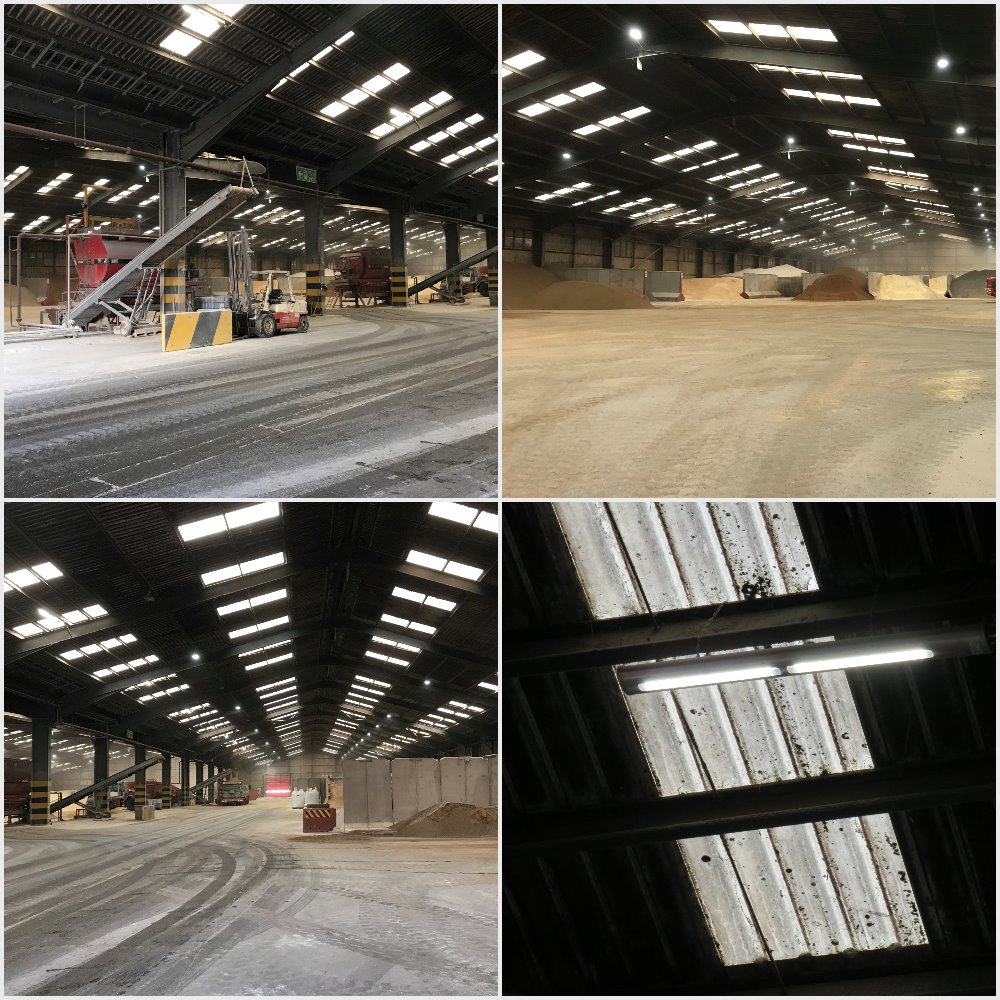

The key objectives were to find suitable low maintenance ATEX light fixtures that could improve the quality of the lighting, were reliable, durable, and could achieve energy savings. The Dialight SafeSite Series was selected, with a combination of the 23,700 lumen High Bay and emergency version of the LED Stainless Steel Linear lighting for the main exit route.

The rewiring of the building to comply with hazardous area regulations, facilitated the opportunity to reposition the high bay lights to improve uniformity and lux levels around the main milling and blending machinery. The drab orange light from the old fittings has been replaced with a clean white light enabling the personnel to operate in greater safety and enhanced colour definition of the bulk feeds.

The switch to LED has multiple benefits for Bristol Port, including halving the energy consumption for the shed, CO2 savings, zero maintenance, and a return on investment of four years. Furthermore, with a 10 year warranty and rated product life of 150,000 hours, this solution eliminates lighting maintenance and significantly improves efficiency and safety in a challenging and volatile environment.